Among all the new buildings, the best embodiment of near-zero energy consumption buildings is the ones equipped with the Building Integrated Photovoltaic (BIPV). BIPV is a technology that integrates solar power generation capability into buildings and related materials. It is a type of distributed photovoltaic power station. In the foreseeable future, all buildings are anticipated to transform from pure energy consumers into independent power stations.

There is no doubt that distributed photovoltaics with BIPV as the outlet has a huge potential. However, 90% of the existing BIPV products on the market are applied directly on building roofs, making it more appropriate to call them BAPV (Building Attached Photovoltaic). Simply put, they are "attached" photovoltaic, because a building can be seen at a glance whether photovoltaic products are installed. In fact, the existing architectural design of distributed rooftop photovoltaics is difficult to integrate with the building itself. BAPV is essentially the "ugly cousin" of BIPV.

BIPV, as the name suggests, should be an integrated product that seamlessly combines photovoltaics and construction. Although BIPV components have photovoltaic power generation performance, they are basically a building material. As a result, the real BIPV should have more prominent building material properties and more diverse architectural application scenarios, including but not limited to roofs and building facades.

Although the average efficiency of photovoltaics used on facades is temporarily lower than that of rooftop photovoltaics, the total facade area of any building is much larger than the roof area. In addition, the incident angle of the sun changes all the time throughout the day. The total potential amount of photovoltaic power generation on the building facade is much greater than the potential total amount of photovoltaic power generation on the roof.

In terms of structure, the mainstream prefabricated BIPV products currently on the market eliminate the photovoltaic brackets required by traditional distributed power stations. They are directly pressed on the color steel tiles and fixed with structural parts to form an integrated module product, which can directly serve as a roof. Building materials are installed on buildings, so the requirements for the strength, hardness, waterproof, windproof, and fireproof performance of BIPV components are higher, and thus the quality requirements for photovoltaic glass are also much higher. A considerable number of traditional BIPVs on the market are inevitably limited by glass performance.

For existing buildings, since the building structure and appearance have been determined, owners usually decide whether to use BIPV products based on the building renovation conditions and the actual conditions of the surrounding environment. If a company can only provide traditional BIPV solutions, it will be stuck in the dilemma of “either generating photovoltaic power but completely altering the appearance of the building and environment, or maintaining the appearance and giving up photovoltaics.” For new buildings, the use of BIPV products can be incorporated into the design planning from the architectural design stage. However, here comes the problem. The appearance options of traditional BIPV products are extremely limited, leaving almost zero space for designers to imagine. Either choose the same existing BIPV products and achieve the awkward situation of "all buildings look the same", or choose traditional building materials and reluctantly say goodbye to a green and low-carbon future.

So far, roofs and curtain walls are the main application scenarios of BIPV. It is not difficult to identify one thing: the so-called "BIPV" currently in the market mainly offers roof photovoltaic color steel tiles, supplemented by monochromatic colored (such as red and green) photovoltaic panels on the curtain wall façade. The majority of manufactures claim the name of BIPV, but exercise the practice of BAPV. What kind of a desperate future we are looking at if our future buildings and living spaces can only look like this?

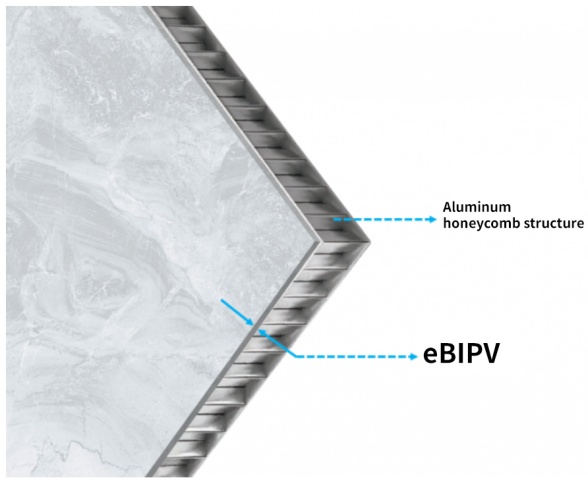

At the end of last year, Chinese CCTV News at the 25th China Hi-Tech Fair reported on the optoelectronic products of an exhibitor named Phomi: econiclay BIPV (English name econiclay BIPV, hereinafter referred to as "eBIPV"). It is understood that except for the aluminum honeycomb structure of this product, what actually generates electricity is a layer of surface material less than 1 cm thick!

As we all know, the attributes and functions of buildings are intertwined to a certain extent, so architectural design has to comprehensively balance all attributes and functions of the building. The humanistic attributes of the architecture require that the overall image of the building has cultural and aesthetic values. The appearance of Phomi's eBIPV, including color, texture, and finish, can be customized. It is completely different from the existing BIPV on the market (products based on glass structures, which are either black/dark blue for silicon wafers, or monochromatic colored, like red, green, etc.). The surface of Phomi's eBIPV can be made to look like natural stone, wood, brick, woven fabric, or leather, with each material category subdivided into many different subtypes. For example, the stone can be travertine, marble, granite, limestone, sandstone and other stone styles that can be found in nature. Another example, the leather texture can be processed into crocodile skin, cowhide, deerskin, snakeskin, etc. These customizable new surface materials allow buildings to better establish a harmonious relationship with the surrounding environment. Offered with such eBIPV products, both designers and owners will no longer struggle with the issue of "using photovoltaics to sacrifice appearance, or giving up photovoltaics to maintain the appearance."

What is the power generation capacity of eBIPV with such an ever-changing appearance? It is reported that the standard eBIPV produced by Phomi can provide 165 W per square meter under international standard sunlight. At present, the mainstream curtain wall BIPV on the market adopts glass structure, and its power generation per square meter is less than 135 W. To improve efficiency, it must be made in dark colors, which means there is no choice in the appearance, which limits the imagination of the design of the building's appearance and beauty.

In addition to the appearance and the photovoltaic performance, eBIPV products have a new standard, which is the carbon emissions during the entire life cycle including manufacturing and service stage. Any BIPV product will produce green and clean energy during use, which indirectly reducing carbon emissions. However, the manufacturing process of glass BIPV products is carried out under extremely high temperature conditions. The entire process must consume a large amount of fossil fuels (such as coal and natural gas), resulting in high level of carbon emissions. The certified carbon emissions of eBIPV by Fumei during the entire life cycle (manufacturing + service) of each watt of product is only 0.26 kg CO2e (carbon dioxide equivalent), which is 58% lower than the carbon emissions of glass BIPV. The carbon emissions of eBIPV manufactured by Fumei have been certified by the international authoritative organization Bureau Veritas for their carbon footprint. Taking into account the service life of photovoltaic products of more than 20 years, the carbon emission level are infinitely close to the definition of zero carbon.

How does Phomi achieve near-zero carbon? The answer lies in Phomi 's proprietary technology: Phomi's eBIPV is mainly made of inorganic solid waste such as sand, stone edges, non-metallic tailings, etc., which has been carefully collected, classified and then being pulverized and transformed into microscopic powder. The particles are modified at low temperature by using specific surfactants so that each particle is wrapped with active ingredients and presents a multi-layered network structure. This typical ecological environmental material (econiclay) is molded into a zero-carbon surface material (coverings) at around 100 degree C. By further manipulating the microstructure of the zero-carbon coverings, the unidirectional light-guiding function of the surface material is realized. Light propagates through the specially-structured surface material and is absorbed by the internal photovoltaic material and converted into electricity. More importantly, this does not affect the colorful appearance of the materials, such as stone-like, wood-like and brick-like. In summary, Phomi's eBIPV employs low temperature + waste utilization + proprietary technology to achieve near-zero carbon.

It is well known that the Smarter E Europe (TSEE) is the world's largest and most influential solar professional trade fair, attracting leading international companies in the industry. As TSEE draws near, it is thrilled to learn that this product will be unveiled at the event.

The Smarter E Europe 2024

Date: June 19-21, 2024

Address: Messe München, Germany

Booth Number: FM.704/61

Media Contact

Company Name: PHOMI

Contact Person: Media Relations

Email: Send Email

Country: China

Website: https://www.phomi.com/